Resources-demo

TORCSTAR BOLTING TOOLS - ISO 9001 : 2015

Bolting Theory

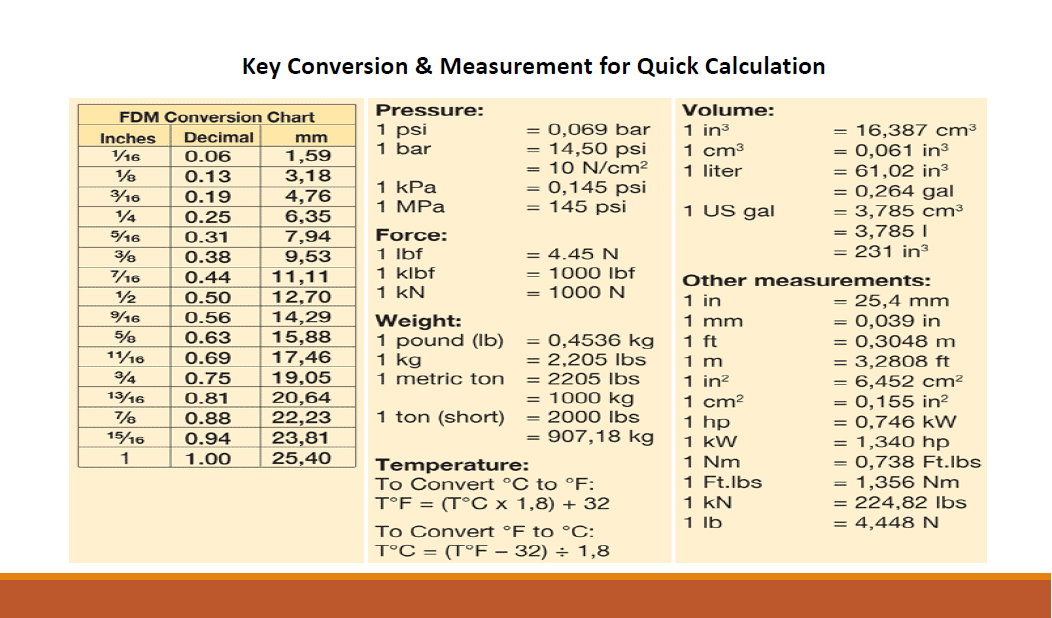

- All Torquing tools are of 700 bar pressure.

- Torquing includes Tightening and Loosening of nuts.

- For Tightening, torque required is as per A/F to Torque chart.

- For opening or loosening of nuts, torque required is 2.5 times of tightening torque.

- Tensioning tools include use of Bolt Tensioners. This is only tool that works on 1500 bar pressure and also pumps are different for Bolt tensioners which are 1500bar.

Tools Used for Bolting Operations

GENERAL HAND TOOLS

- Impact Socket

- Hex Bit Sockets

- Slugging /Hammering Spanners

- Hex Reducers

- Manual Torque Wrenches

- Torque Multipliers

- Square Adapters

- Ratchets / Extension Bars

HYDRAULIC TOOLS

- Hydraulic Torque Wrench

- Power Pack

- Twin Line Hoses

- Hydraulic Jacks

- Hand Pump

- Electric Torque Wrench

- Pneumatic Torque Wrench

- Nut Splitters

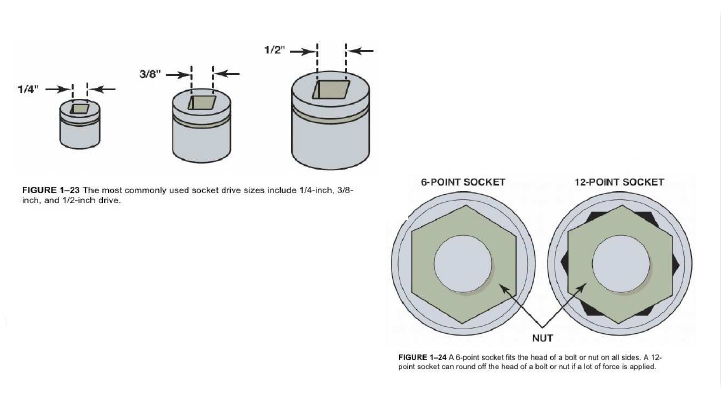

Impact Socket

Selection is based on

- Square Drive Size

- Across Flat size (A/F)

- Overall Length

- No. of points – 6pt or 12pt

For example

- Impact socket 1” Sq. Dr x 46mm A/F

- Standard Length – 6pt

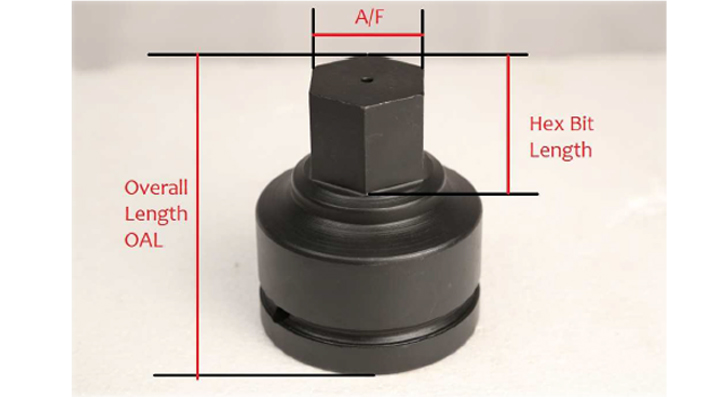

Hex Bit Socket

Selection is based on

- Square Drive Size

- Across Flat size (A/F)

- Overall Length (L)

- Hex Bit Length (H)

For example

- Hex Bit Socket 1” Sq. Dr x 32mm A/F

- OAL – 120 mm and Hex Bit Length 50mm

Hex Reducers

Selection is based on

- Male part of Hex Reducer = Hex Link Size

- Required Female A/F size

- Length of Hex Reducer (Width of Hex Link)

For example

- Hex Reducer of 60mm Male Hex to

- 55mm A/F (Female).

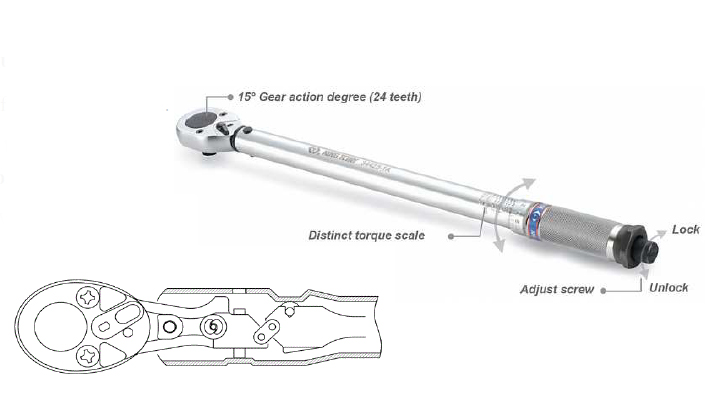

Manual Torque Wrench

Selection is based on

- Model is selected as per Required Torque.

- Square Drive is to be noted for socket selection.

- Manual Torque Wrench is to be used for approx torque starting from 10Nm up to 1500Nm.

- Variants of Manual Torque Wrench are as below :

- Interchangeable Type

- Preset Type

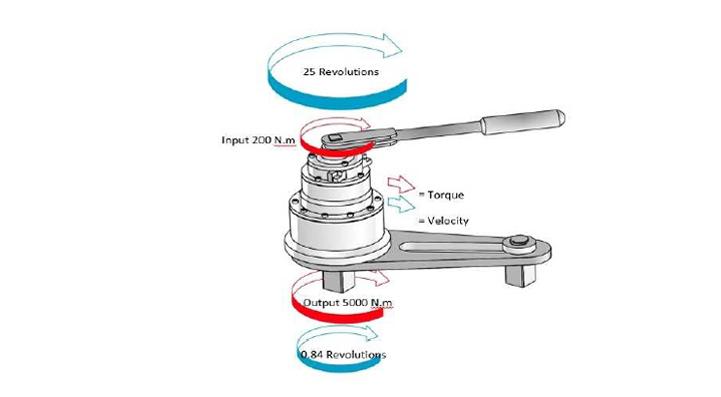

Torque Multipliers

Selection is based on

- Model is selected as per Required Torque.

- Manual Torque Wrench is selected as per Torque Multiplier Model.

- Output Square Drive is to be ensured for socket selection to be mounted on nut.

- Torque Chart is to be followed with reference to model and Multiplication factor.

Hydraulic Torque Wrench

Selection is based on

- Square Drive OR Hex Drive Type

- Torque Required

- Nose Radius

- Different size of Sockets OR Hex Reducers need to be offered with Torque Wrench.

- Pump used to drive HTW will be either Pneumatic or Electric.

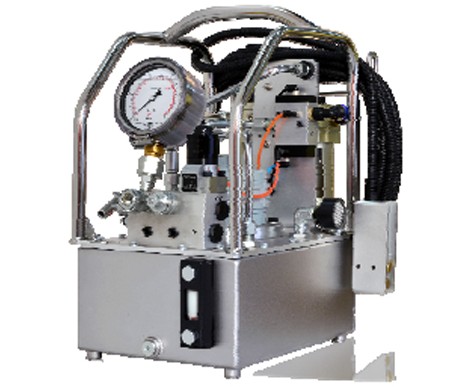

Power Pack And Hose

Electric Pump 700 bar

Twin Line Hose For HTW – ¼”

Pneumatic Pump 700 bar

Jacks & Accessories

- Hydraulic Jack with 3/8 inlet

- Hose with 3/8” Outlet

- Hand Pump – 700 bar

- Pressure gauge – 700 bar / 10000 psi

- Manifold to connect more than one jack.

Bolting Methodology

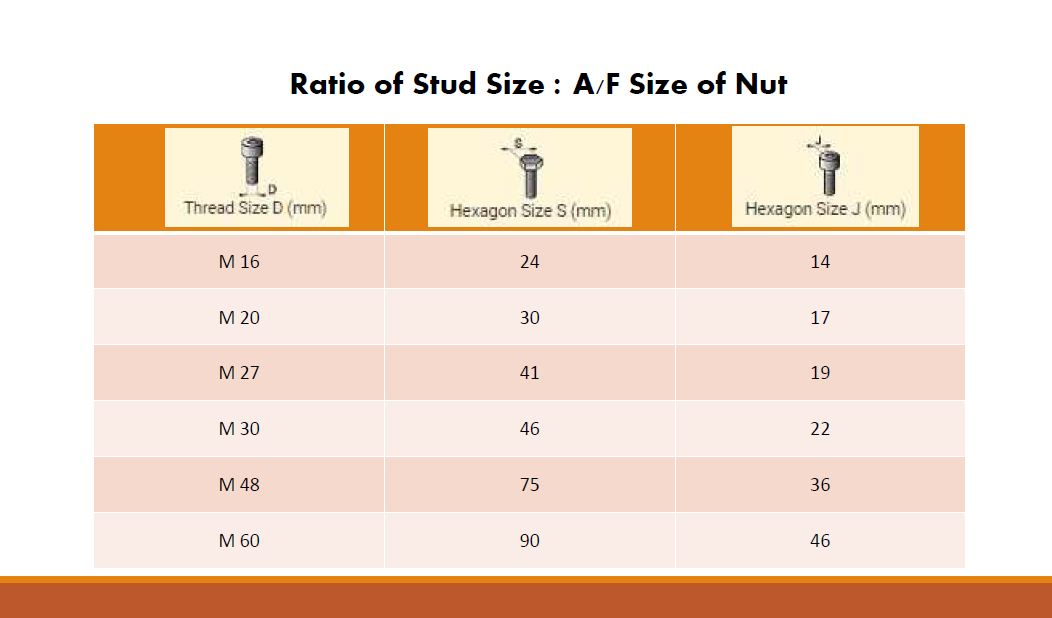

- To ask end user about A/F size of Nut.

- To ask if they are using any lubricant on thread and grade of nut. (OPTIONAL)

- To ask whether there is sufficient space around nut for mounting of tool and distance of next nut.

- Derive torque from chart based on A/F size and grade of nut.

- Suggest either manual torque wrench or Hydraulic torque wrench based on torque.

- If torque is up to 1500Nm then suggest manual torque wrench or Torque Multipliers and if torque is above 1500-2000Nm then suggest hydraulic torque wrench.

- They will need sockets along with Square drive hydraulic torque wrench. (Sockets not required with hex type hydraulic torque wrench).

- Square drive size of socket will be as per square drive size of tool.

- A/F Size of socket will be as per A/F size of nut (application)

- If they prefer HTW then ask them for pump based on electric or air driven criteria. (Prefer electric one)

APPLICATIONS

Hydraulic Torque Wrench

Hydraulic Jacks

Manual Torque Wrench

Torque Multiplier

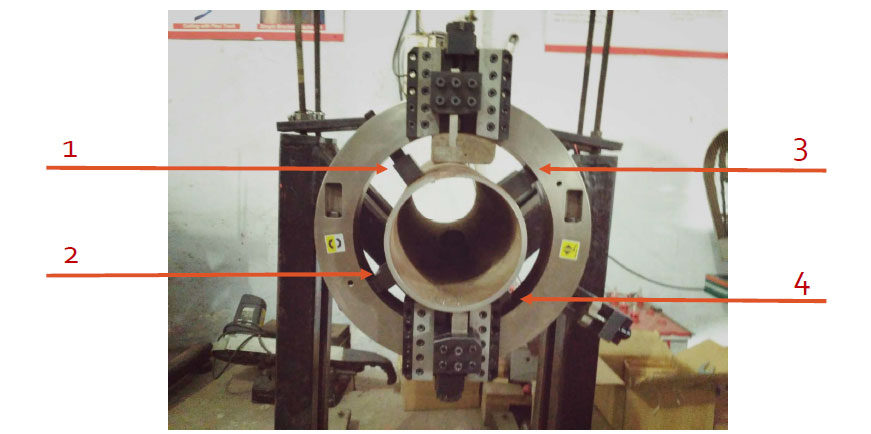

Pipe Cutting Machine

Key Features

- Frame: Steel / Aluminum combination design gives High Strength to Cut / Bevel thick wall pipes, while keeping Machine Light Weight.

- Special Design : Cutting Head Assembly, Drive Assembly & Bearings provide rigidity of operation to take care Axial & Radial force reactions.

- Automatic Tool Feeding.

- Interchangable Hydraulic / Pneumatic Drives

Step 1 - Unpack Frame of Machine

Step 2 - Select Jaw as per Pipe OD

Step 3 - Assemble Jaws at four ends of Machine

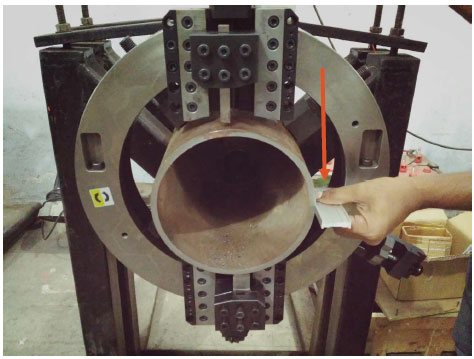

Step 4 - Arrange Frame Right Angle to Pipe

Hammer it with Mallet at surface where it is not right angle

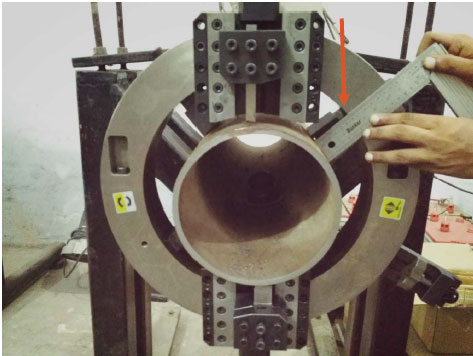

Step 5 - Check gap between frame and pipe

Ensure that same gap is kept on opposite side to centre it

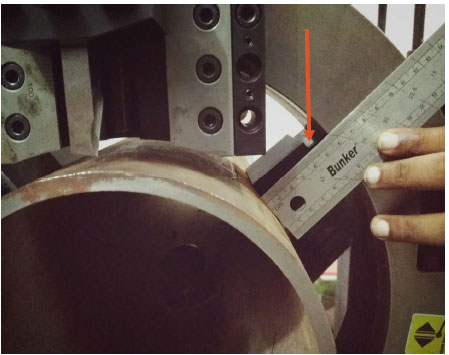

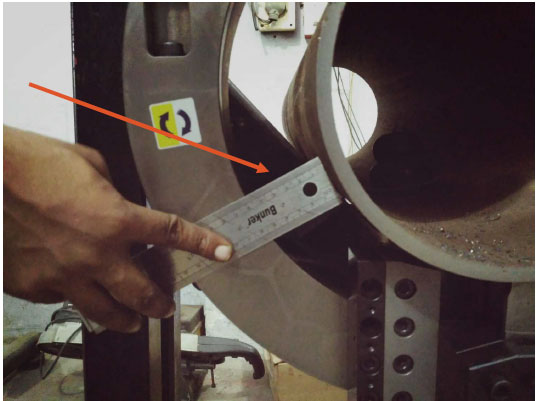

Step 6 - Check gap between frame and pipe

Gap should be same as per previously measured side

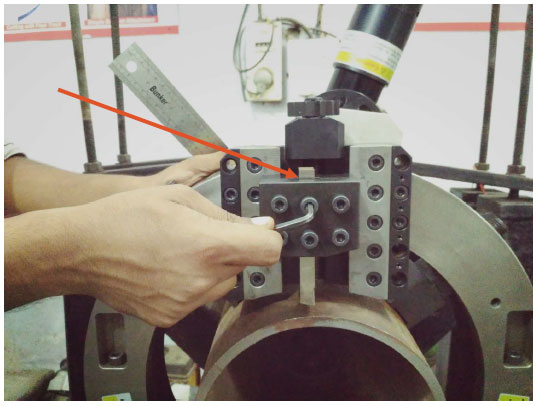

Step 7 - Insert Cutting tool at one side and Bevelling on other side

Tool can be tightened by fixing two centre allen bolts

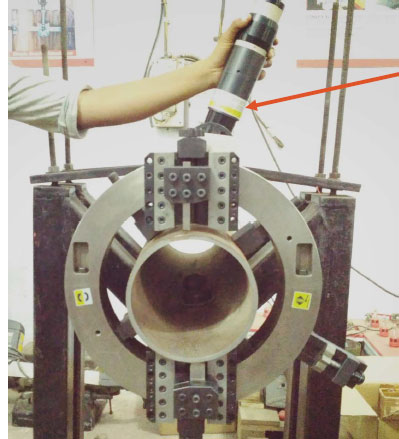

Step 8 - Attach Pneumatic / Electric drive to frame

English

English