وصف المنتج

Torc Star impact sockets are designed for professional tool users. They are engineered specifically for use with impact tools using the most up to date industrial specifications. Impact sockets are made with thicker walls and tempered to a lower hardness so as not to shatter under the impacts. They are typically finished in black oxide rather than the chrome plating typical of the hand-tool variety. Hand-tool sockets should never be used with impact wrenches as they will shatter. Since impact sockets are used in demanding applications, impact sockets are designed to sustain the impacts. Look inside the square drive hole for a mark in the metal that looks like it’s been gouged with a fingernail. This indicates that the drive has been formed by pushing a rod through the metal during the forging process, resulting in a stronger surface. Check where the six inside walls of the socket meet. Rounded corners let the walls of the socket grip a bolt, rather than the weaker edges. Inner walls that meet at sharp points are likely to crack under heavy use.

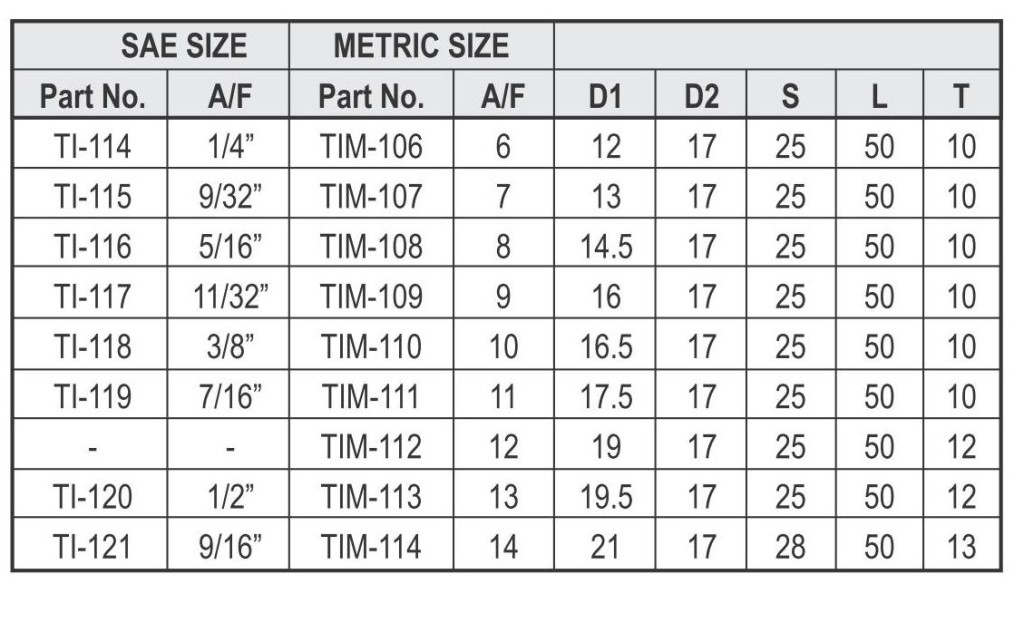

Impact sockets are available in different sizes and types. A few common types that are used are as under:

- 6 Point Standard Impact Sockets

- 6 Point Deep Impact Sockets

- 12 Point Standard Impact Sockets

- 12 Point Deep Impact Sockets

- 4 Point Standard

- 8 Point Standard

- Thin Wall Impact Sockets -Standard

- Thin Wall Impact Sockets-Deep

NOTE : TO ORDER DEEP SOCKETS ADD “L” AFTER PART NO.

English

English